Precision Takes Priority: The Quest for Ideal Machining Parts Supplier

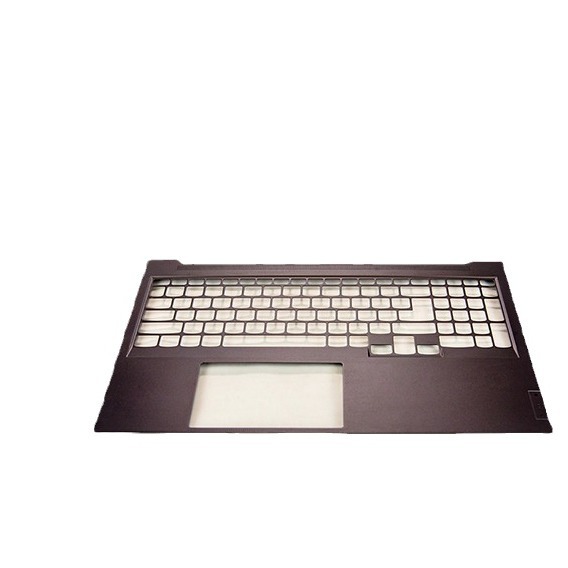

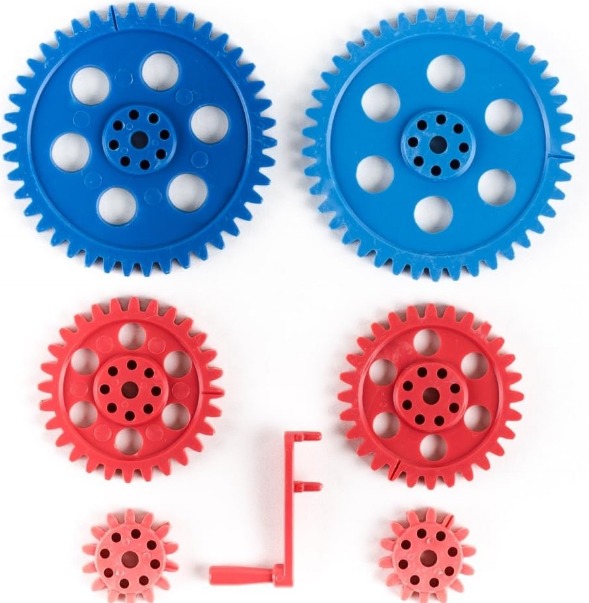

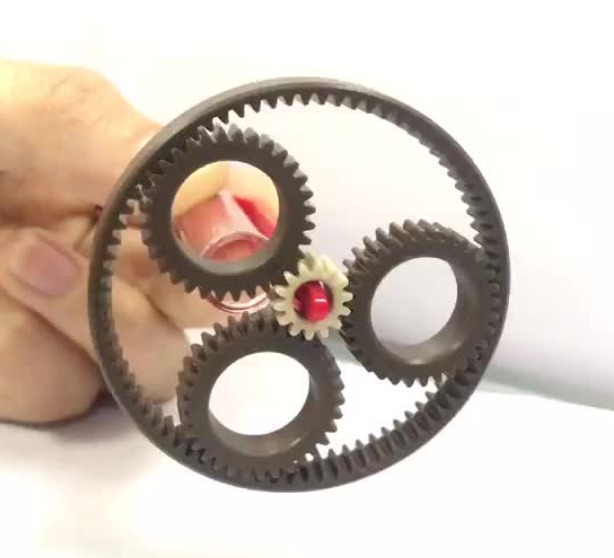

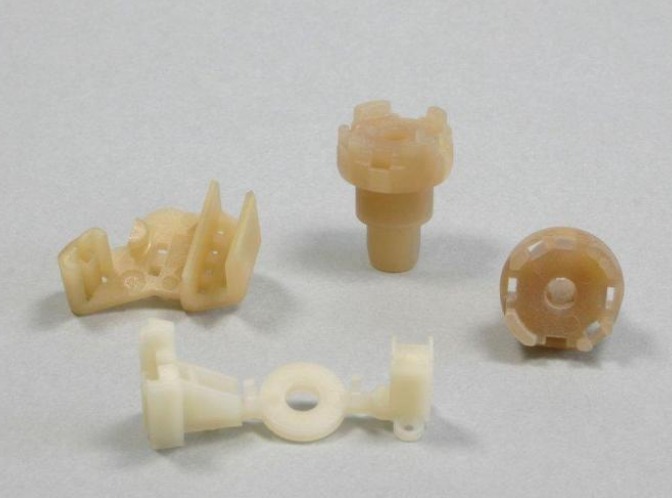

1. Understanding the Crucial Role of Machining Parts Suppliers In the intricate web of modern manufacturing, machining parts suppliers stand as the linchpin, holding together the diverse sectors such as automotive, aerospace, electronics, and medical. Their role is not merely about supplying components; it is about enabling the creation of high - performance, reliable end […]