How to Find the Best Plastic Injection Mold Shops

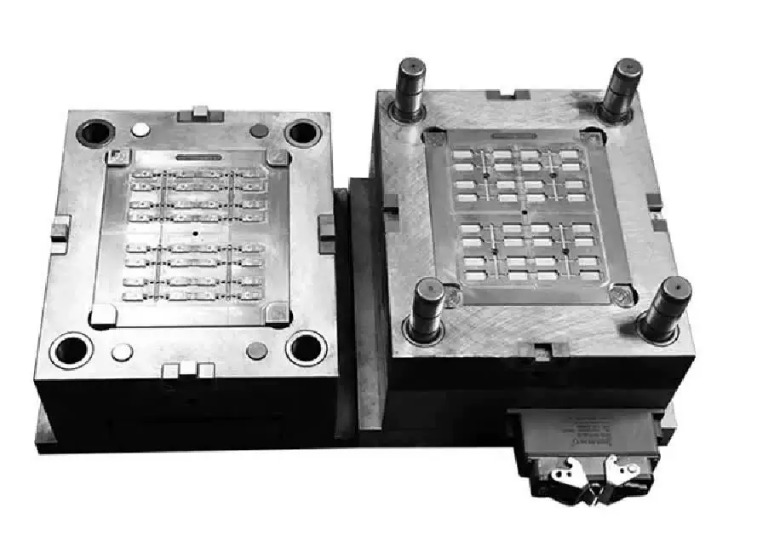

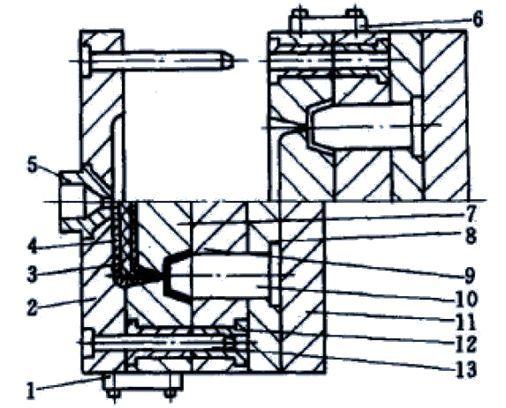

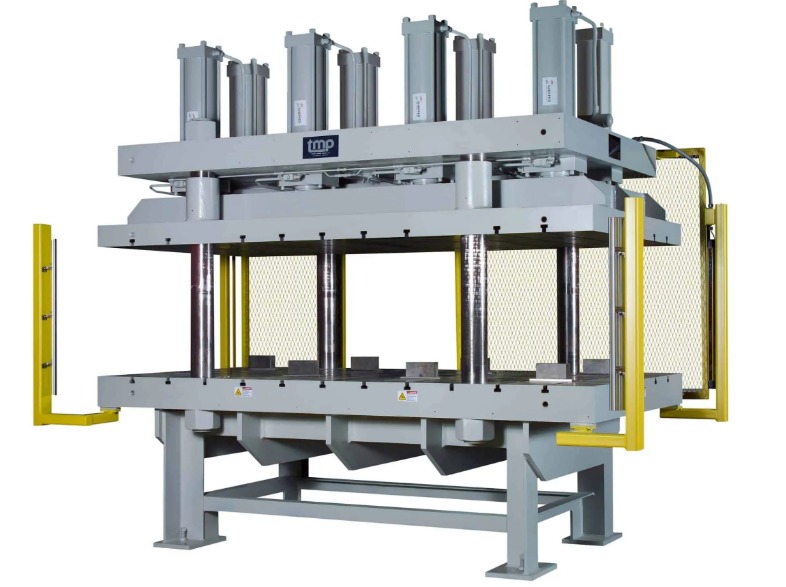

Introduction In the vast realm of plastic product manufacturing, the role of plastic injection mold shops cannot be overstated. These shops are the architects behind the creation of molds that shape countless plastic products we use in our daily lives, from the tiny components in our electronic devices to the large parts in automobiles. The […]