Custom Plastic Injection Molding: A Guide for Beginners

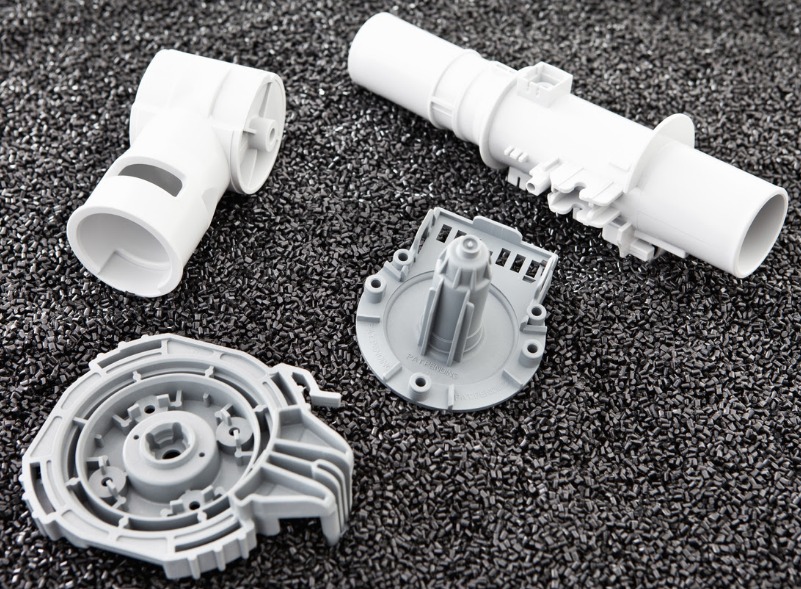

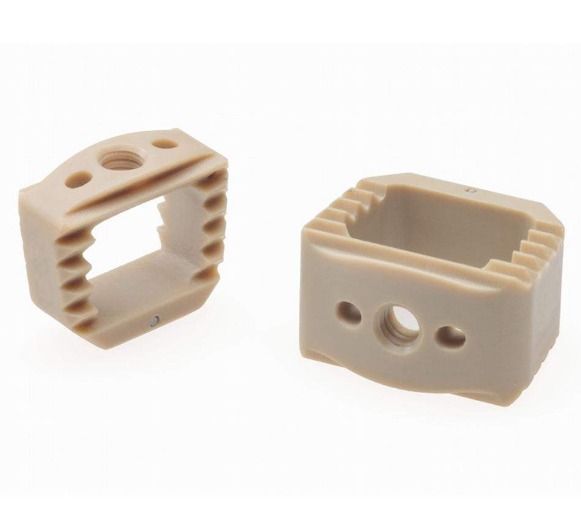

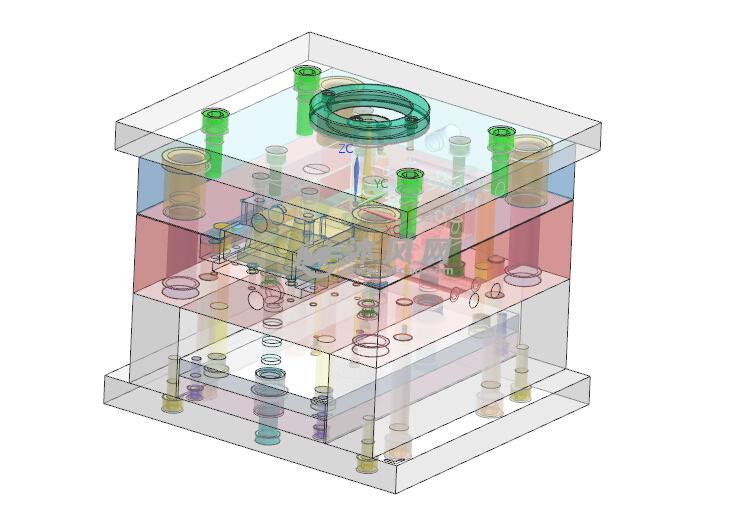

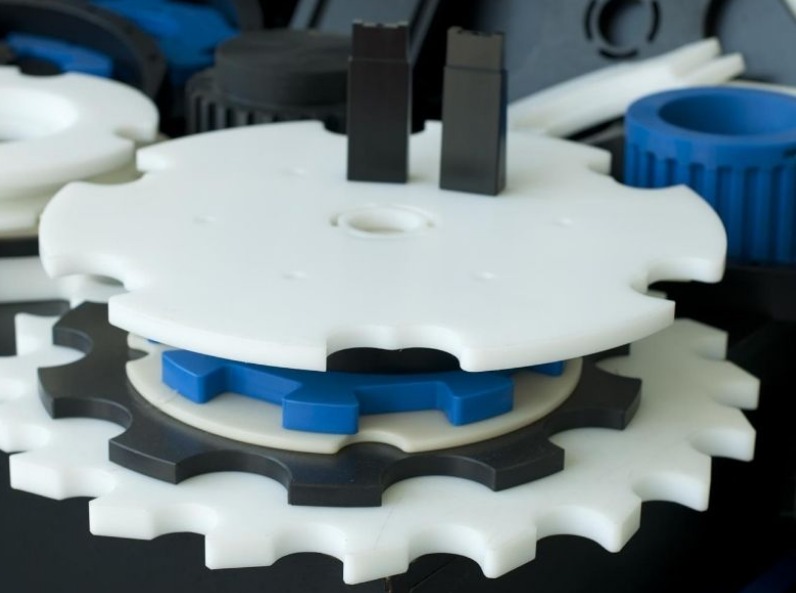

What is Custom Plastic Injection Molding? Custom plastic injection molding is a manufacturing process that creates custom - designed plastic parts. It's widely used in various industries, from consumer electronics to automotive, and even in medical device manufacturing. For instance, the casings of your smartphone, the interior components of your car, and many disposable medical […]