Injection Pressure in Injection Moulding: A Comprehensive Guide

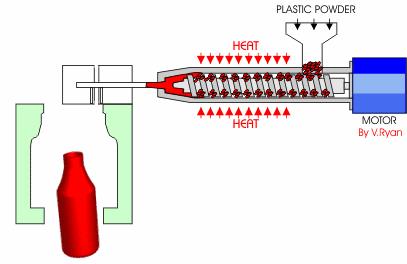

Understanding Injection Pressure Definition and Basics Injection pressure, in the context of injection moulding, is the force exerted on the molten plastic material to push it into the mould cavity. This pressure is crucial as it ensures that the plastic fills every intricate detail of the mould, creating a high - quality, accurately shaped final […]