Introduction

What is a Three Plate Injection Mould?

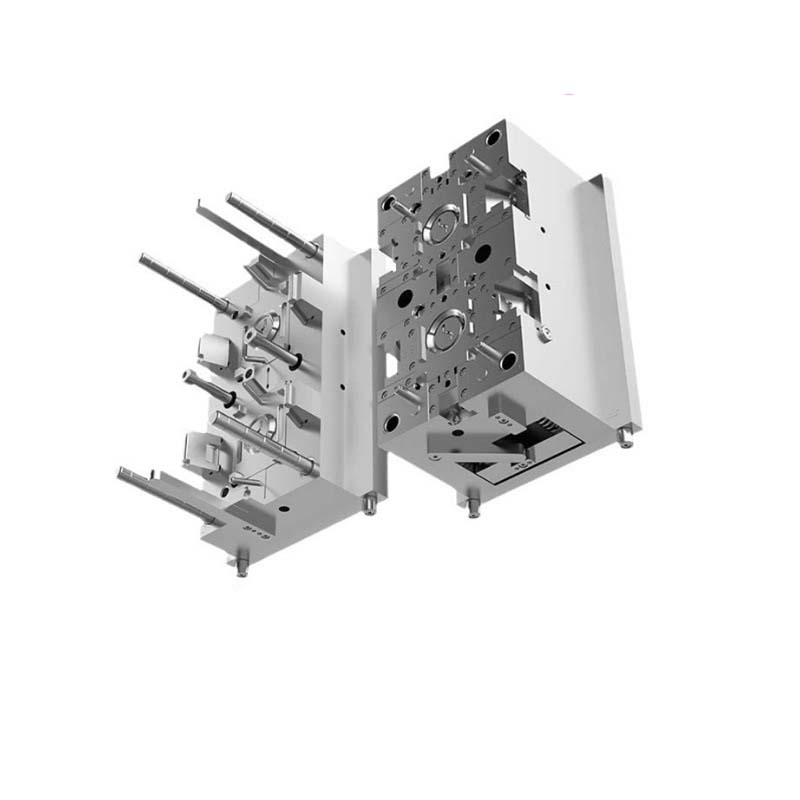

A three - plate injection mould is a specialized tool used in the injection moulding process, which is a widely adopted manufacturing method for producing plastic parts. It consists of three main plates: the fixed clamping plate, the moving clamping plate, and an additional middle plate (also known as the stripper plate or runner plate). This design allows for a more complex and precise moulding operation compared to two - plate injection moulds.

In a three - plate injection mould, the separation of the plates during the mould - opening sequence enables the automatic removal of the runner system (the channels through which the molten plastic flows into the cavity) from the moulded part. This is a significant advantage as it reduces the need for manual trimming of the runners, saving both time and labor costs in the post - processing stage. For example, in the production of small, intricate plastic components such as electronic connectors, the automatic runner separation feature of a three - plate injection mould ensures high - volume production with consistent quality.

Working Principle

Step - by - Step Process

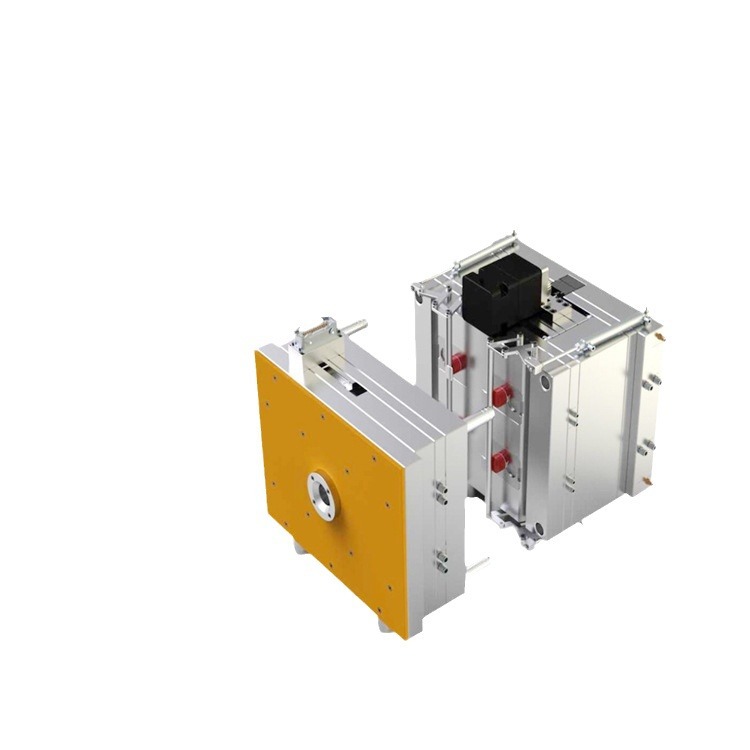

- Clamping: The mould - closing process begins with the moving clamping plate being driven towards the fixed clamping plate by the injection moulding machine's clamping mechanism. The three - plate injection mould firmly closes, creating a closed cavity where the plastic part will be formed. The clamping force applied must be sufficient to prevent the mould from opening during the injection and packing stages. For example, for a medium - sized three - plate injection mould used to produce plastic automotive interior parts, a clamping force of around 500 - 1000 tons might be required, depending on the size and complexity of the part.

- Injection: Once the mould is clamped shut, the injection unit of the machine comes into action. Molten plastic, which has been heated to the appropriate processing temperature in the barrel, is forced through the sprue (the main channel connecting the injection unit to the mould) and into the runner system of the three - plate mould. The runner system distributes the molten plastic evenly to the cavities. In a multi - cavity three - plate injection mould for producing small electronic components, the injection time might be in the range of 1 - 3 seconds, ensuring that the molten plastic fills all the cavities quickly and uniformly.

- Packing and Holding: After the cavities are filled with molten plastic, a packing pressure is applied to compensate for the shrinkage of the plastic as it cools and solidifies. This pressure is maintained for a certain period (the holding time), typically a few seconds, to ensure that the final part has the correct dimensions and density. For high - precision parts, such as medical device components, a precise packing and holding process is crucial to meet the tight tolerance requirements.

- Cooling: During and after the packing and holding stages, the mould is cooled. Cooling channels within the mould plates circulate a cooling medium (usually water) to remove the heat from the molten plastic, causing it to solidify into the shape of the cavity. The cooling time is a significant factor in the overall cycle time of the injection moulding process. For large plastic parts, the cooling time can be several minutes. For instance, in the production of a plastic automotive bumper using a three - plate injection mould, the cooling time might be around 3 - 5 minutes to ensure that the part has cooled sufficiently for easy demoulding without distortion.

- Mould Opening: Once the plastic part has cooled and solidified, the mould - opening sequence starts. The moving clamping plate moves away from the fixed clamping plate. In a three - plate injection mould, the middle plate (runner plate) separates first, pulling the runner system away from the cavities. This allows for the automatic removal of the runner, which is a distinct advantage of the three - plate design.

- Ejection: After the mould is fully opened, the ejection system comes into play. Ejector pins, which are located in the moving half of the mould, push against the part or a stripper plate, forcing the solidified plastic part out of the cavity. In some cases, additional ejection mechanisms such as lifters or air ejection might be used for complex - shaped parts. For example, for parts with undercuts, lifters are designed to move the undercut portion of the part out of the way before the main ejection process.

Key Components and Their Roles

- Fixed Clamping Plate: This is the stationary part of the mould and is attached to the fixed platen of the injection moulding machine. It holds the fixed half of the cavity (the cavity insert) and the sprue bushing, which guides the molten plastic from the injection nozzle into the mould. The fixed clamping plate provides a stable base for the mould during the injection and clamping processes.

- Moving Clamping Plate: As the name implies, this plate moves towards and away from the fixed clamping plate during the mould - closing and mould - opening operations. It houses the moving half of the cavity (the core insert), the ejection system (ejector pins, ejector plates), and in some cases, components of the runner system. The moving clamping plate is responsible for ejecting the finished part from the mould after it has cooled and solidified.

- Middle Plate (Runner Plate): This is a unique feature of the three - plate injection mould. It separates the runner system from the cavities during the mould - opening process, enabling the automatic removal of the runner. The middle plate also contains channels (runners) that distribute the molten plastic from the sprue to the gates, which are the openings that allow the plastic to enter the cavities.

- Cavity and Core Inserts: The cavity insert is the female part of the mould that defines the outer shape of the plastic part, while the core insert is the male part that defines the inner shape (if the part has a hollow section or internal features). These inserts are usually made of high - quality steel, such as P20 or H13, which can withstand the high pressures and temperatures during the injection moulding process. For example, in the production of a plastic bottle cap, the cavity insert will have the shape of the outer surface of the cap, and the core insert will form the inner threads.

- Runner System: This includes the sprue, runners, and gates. The sprue is the main channel through which the molten plastic enters the mould from the injection nozzle. Runners are the secondary channels that distribute the plastic from the sprue to the gates. Gates are the small openings that connect the runners to the cavities. The design of the runner system is crucial for ensuring even distribution of the molten plastic to all cavities in a multi - cavity mould and for minimizing pressure losses during injection. For example, in a four - cavity three - plate injection mould for producing plastic toy parts, the runner system is designed to deliver the molten plastic to each cavity with the same pressure and flow rate.

- Ejection System: Comprising ejector pins, ejector plates, and sometimes lifters, the ejection system is responsible for removing the solidified plastic part from the mould after it has cooled. Ejector pins are small rods that are placed in strategic locations around the cavity. When the mould is opened, the ejector plates push the ejector pins forward, which in turn push the part out of the cavity. Lifters are used for parts with undercuts, which are features that prevent the part from being removed directly from the mould. The lifters move the undercut portion of the part out of the way, allowing the part to be ejected.

Comparison with Other Moulds

Two - Plate Injection Mould

Two - plate injection moulds are another common type in the injection moulding industry. Here is a comparison between three - plate and two - plate injection moulds in terms of several key aspects:

| Aspect | Three - Plate Injection Mould | Two - Plate Injection Mould |

| Structure | Consists of three plates: fixed clamping plate, moving clamping plate, and middle (runner) plate. This allows for a more complex runner system separation. | Comprises only two main plates: the fixed and the moving clamping plates. The runner and the part are ejected together in most cases. |

| Cost | Generally more expensive due to the additional plate and more complex design. The manufacturing process for a three - plate mould is more intricate, involving more machining operations and potentially more components. | Less costly as it has a simpler structure. There are fewer parts to manufacture and assemble, reducing both material and labor costs. |

| Runner System | Enables automatic separation of the runner from the part during mould opening. This results in less post - processing labor as the runner does not need to be manually removed from the part. | The runner and the part are typically ejected together, which means that additional post - processing steps are required to separate the runner from the part. This can increase production time and cost. |

| Gating Options | Offers more flexibility in gating. Multiple gating points can be easily implemented, which is beneficial for parts with complex geometries or for achieving uniform filling. | Limited in gating options compared to three - plate moulds. Usually, it has fewer gating points, which may not be suitable for all part designs. |

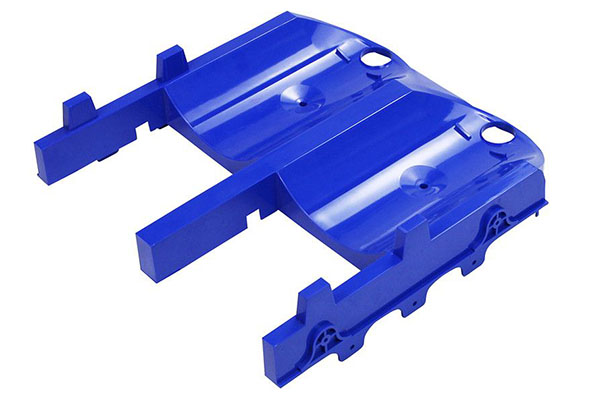

| Suitability for Products | Ideal for producing small, complex parts with tight tolerances and multiple cavities. For example, it is often used in the production of electronic components, such as connectors and small plastic gears. | More suitable for larger, simpler parts where cost - effectiveness is a major concern. For instance, it can be used for manufacturing large plastic containers or simple automotive exterior parts. |

Other Types of Moulds (e.g., Compression Mould, Blow Mould)

- Compression Mould: Compression moulding involves placing pre - measured amounts of raw material (such as thermosetting plastics or rubber compounds) into a heated mould cavity. The mould is then closed, and pressure is applied to compress the material, causing it to flow and fill the cavity. One key difference from a three - plate injection mould is that compression moulding is mainly used for thermosetting materials, while three - plate injection moulds are used for thermoplastics. Also, compression moulding generally has a longer cycle time as the curing process of thermosetting materials requires heat and time for chemical reactions to occur. In contrast, three - plate injection moulds can have relatively shorter cycle times due to the nature of thermoplastic processing, where the plastic is melted and cooled to form the part.

- Blow Mould: Blow moulding is a process used to form hollow plastic parts, such as bottles and containers. In blow moulding, a parison (a tube - like piece of molten plastic) is placed in a mould cavity, and then air is blown into the parison to inflate it and force it against the walls of the mould. Three - plate injection moulds, on the other hand, are used to produce a wide range of plastic parts, both solid and with complex internal features. Blow moulding is highly specialized for creating hollow objects, while three - plate injection moulds offer more versatility in terms of the shapes and types of parts they can produce, including parts with intricate details and multiple components in a single moulding cycle.

Tips for Choosing the Right Three Plate Injection Mould

Material Considerations

When selecting a three - plate injection mould, material considerations are of utmost importance. The type of plastic to be moulded is a primary factor. Different plastics have varying characteristics such as melt flow rate, shrinkage rate, and temperature resistance. For example, if you are working with high - temperature - resistant plastics like polyetheretherketone (PEEK), the mould material must be able to withstand the high processing temperatures without deforming. Steel grades such as H13 are often used for moulds processing high - performance plastics due to their excellent heat - resistance and strength.

The product batch size also affects the choice of mould material. For low - volume production, less expensive materials like P20 steel might be sufficient. P20 steel has good machinability and can be heat - treated to achieve a reasonable hardness for general - purpose moulding applications. However, for high - volume production, more durable and wear - resistant materials like NAK80 or 718 are preferred. These materials can maintain their dimensional accuracy and surface finish over a large number of moulding cycles, reducing the need for frequent mould replacements and thus lowering long - term production costs.

Manufacturer Reputation and Experience

Opting for a manufacturer with a good reputation and rich experience is crucial. A well - established manufacturer is more likely to have the technical expertise and advanced manufacturing equipment to produce high - quality three - plate injection moulds. They will have a deep understanding of the design principles, manufacturing processes, and quality control measures required for these complex moulds.

An experienced manufacturer can also provide valuable advice on mould design optimization. They can help you select the most suitable gating system, runner layout, and cooling channels based on your product requirements. For instance, they may recommend a specific type of gate to minimize weld lines or a particular cooling channel configuration to ensure uniform cooling of the part. Additionally, a reputable manufacturer will typically offer better after - sales service, including prompt response to any mould - related issues, spare parts availability, and technical support for mould maintenance and repair.

Customization Options

Customization is often necessary to meet specific product requirements. When choosing a three - plate injection mould, it's important to consider the customization options offered by the manufacturer. This includes the ability to design unique cavity and core shapes to create parts with complex geometries. For example, if your product has intricate internal features or undercuts, the mould needs to be customized with special ejection mechanisms such as lifters or slides.

The manufacturer should also be able to customize the runner system and gating locations according to your product's size, shape, and desired filling pattern. Customizing the runner system can improve the efficiency of plastic flow and reduce material waste. Some manufacturers may also offer customization in terms of the mould's surface finish. If your product requires a high - gloss or textured surface, the manufacturer should be able to achieve the desired finish through appropriate machining or surface treatment processes.

Yigu Technology's View

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values the three - plate injection mould in our manufacturing processes. With years of experience in custom production, we've found that three - plate injection moulds offer unique advantages for creating complex and high - precision non - standard parts.

Our team has extensive knowledge in designing and optimizing three - plate injection moulds. We can customize every aspect of the mould, from the runner system to the cavity design, to meet the specific requirements of different materials and product geometries. For example, when dealing with complex plastic - metal composite parts, our expertise in three - plate injection moulds allows us to achieve precise integration of different materials, ensuring high - quality end - products.

Moreover, we understand the importance of cost - effectiveness in custom manufacturing. The automatic runner separation feature of three - plate injection moulds reduces post - processing costs, which is a significant advantage in our production. We are committed to providing our clients with top - notch custom non - standard plastic metal products by leveraging the capabilities of three - plate injection moulds.