What Key Applications of Automotive Injection Molding?

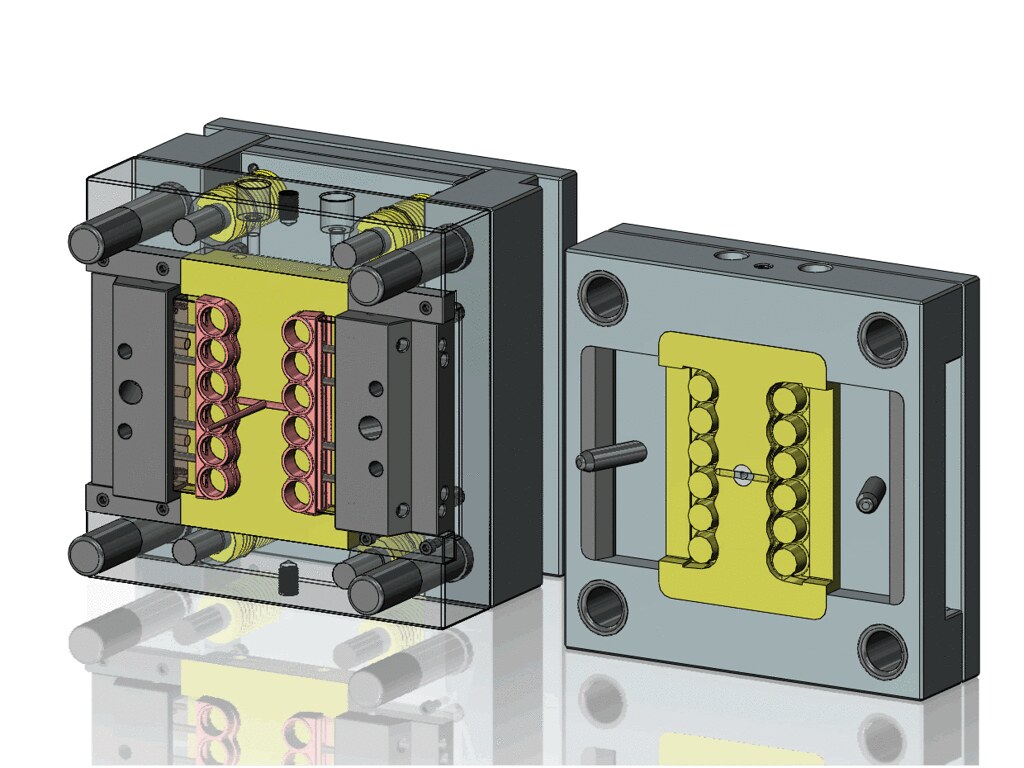

Introduction Definition and Process of Automotive Injection Molding Automotive injection molding is a manufacturing process that plays a pivotal role in the production of various components within the automotive industry. In essence, it involves injecting molten plastic material into a precisely designed mold cavity. This process begins with the plastic material, often in pellet form, […]