Introduction

Connector injection molding is a specialized manufacturing process that has become integral to the production of connectors across various industries. It involves injecting molten plastic or other materials into a precisely designed mold to create connector components with high precision and consistency. This method has revolutionized the production of connectors, offering a range of benefits over traditional manufacturing techniques.

Yigu Technology is to delve deep into the advantages and applications of connector injection molding. Whether you're an engineer looking for efficient manufacturing solutions, a business owner aiming to optimize production, or simply someone interested in the world of manufacturing, understanding the capabilities of connector injection molding can provide valuable insights. By exploring its benefits and real - world applications, we hope to help you make informed decisions when it comes to manufacturing or selecting connector - based products.

What is Connector Injection Molding?

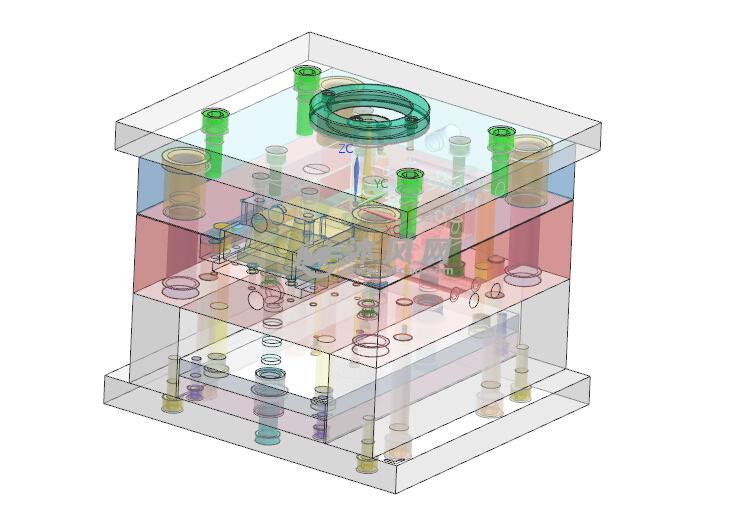

Connector injection molding is a manufacturing process that involves injecting molten materials, typically thermoplastic polymers, into a mold cavity to create connector components. The process begins with the raw material, usually in the form of small pellets, which are fed into a heated barrel. Inside the barrel, a screw - like mechanism, known as a reciprocating screw, rotates and moves back and forth. This action not only mixes the plastic pellets but also generates heat through friction, melting the plastic into a viscous, flowing state.

Once the plastic is fully molten, the reciprocating screw moves forward, forcing the molten plastic under high pressure through a nozzle and into a precisely designed mold. The mold is made up of two or more parts that fit together to form a cavity in the exact shape of the desired connector. The high - pressure injection ensures that the molten plastic fills every intricate detail of the mold cavity, replicating features such as pins, sockets, and channels with great accuracy.

After the mold cavity is filled, the plastic is allowed to cool and solidify. This cooling process is carefully controlled to ensure uniform solidification and dimensional stability of the connector. Once the plastic has hardened, the mold opens, and the newly formed connector is ejected. In some cases, post - processing operations such as trimming excess material (flash), deburring, and surface finishing may be performed to achieve the final product specifications.

This process can also be used with other materials like liquid silicone rubber (LSR) for applications that require high - flexibility or biocompatibility. Additionally, insert molding can be combined with connector injection molding. In insert molding, pre - formed metal or other components are placed inside the mold before injection. The molten plastic then encapsulates these inserts, creating a single, integrated part with the advantages of both materials.

Advantages of Connector Injection Molding

High - Precision Manufacturing

Connector injection molding excels in high - precision manufacturing. Modern injection molding machines and advanced mold - making techniques enable the production of connector components with extremely tight tolerances. For Yigu Technology example, in the production of high - speed data connectors, the dimensional accuracy can be controlled within a tolerance range of ±0.01 - 0.05mm. This level of precision is far beyond what many traditional manufacturing methods can achieve. In contrast, traditional machining processes might have a tolerance range of ±0.1 - 0.5mm, which is significantly less accurate. The high - precision manufacturing of connector injection molding ensures that the connectors fit perfectly with other components, reducing the risk of signal interference and improving the overall performance and reliability of the electrical or mechanical systems they are part of.

Cost - Efficiency in Mass Production

In mass production, connector injection molding offers remarkable cost - efficiency. Although the initial investment in mold design and manufacturing can be substantial, the cost is spread out over a large number of produced parts. For instance, if a mold costs \(50,000 and is used to produce 1,000,000 connector components, the mold cost per part is only \)0.05. Additionally, injection molding has a high production speed. A modern injection molding machine can produce hundreds or even thousands of connector parts per hour, depending on the complexity of the product. This high - speed production reduces the labor cost per unit, as fewer man - hours are required to produce a large quantity of parts. As a result, the overall unit cost of the connector components in mass production is significantly lower compared to other manufacturing methods that are less efficient in high - volume production.

Design Flexibility

Connector injection molding provides unparalleled design flexibility. It allows for the creation of connectors with complex shapes and structures that would be extremely difficult or even impossible to achieve with other manufacturing processes. For example, connectors with internal channels for wire routing, intricate locking mechanisms, or multi - level contact surfaces can be easily manufactured through injection molding. Some specialized connectors for medical devices may have a unique shape that needs to fit precisely within a medical instrument while also providing secure electrical connections. Injection molding enables the production of these connectors with all their complex features in a single manufacturing step, eliminating the need for multiple assembly operations and reducing the risk of component failure due to improper assembly.

Material Diversity

A wide range of materials can be used in connector injection molding. Common thermoplastic materials include acrylonitrile - butadiene - styrene (ABS), polycarbonate (PC), and polyethylene (PE). ABS is known for its good impact resistance, surface finish, and ease of processing, making it suitable for general - purpose connectors in consumer electronics. PC offers high strength, heat resistance, and excellent electrical insulation properties, which is ideal for connectors used in high - temperature or high - voltage applications. Liquid silicone rubber (LSR) can be used for applications that require high flexibility and biocompatibility, such as connectors in medical devices. Each material has its own set of characteristics, allowing manufacturers to select the most appropriate one based on the specific requirements of the connector application, whether it's for automotive, aerospace, or industrial use.

High Production Efficiency

The injection molding process is highly automated, contributing to high production efficiency. Once the injection molding machine is set up with the correct parameters, it can operate continuously with minimal human intervention. The production cycle time for connector injection molding is relatively short. For simple connector components, the cycle time can be as short as 10 - 30 seconds, including the injection, cooling, and ejection phases. This short cycle time, combined with the ability to produce multiple parts in a single mold (multi - cavity molds), enables manufacturers to meet large - scale order demands quickly. For example, in the production of connectors for the consumer electronics industry, where high - volume production is the norm, injection molding can ensure that millions of connectors can be produced within a relatively short period, keeping up with the fast - paced market demands.

Applications of Connector Injection Molding

Connector injection molding has found widespread applications across various industries due to its numerous advantages. Here are some of the key areas where it plays a crucial role:

In the Automotive Industry

In the automotive industry, connector injection molding is used in a wide range of components. For Yigu Technology example, in the engine control system, connectors are essential for transmitting signals between sensors, actuators, and the engine control unit (ECU). These connectors need to be highly reliable as any malfunction could lead to engine performance issues or even safety hazards. According to industry statistics, a modern car can have over 100 different connectors, and injection - molded connectors account for a significant portion of them.

The safety - critical airbag system also relies on injection - molded connectors. These connectors must ensure a stable electrical connection to trigger the airbags instantaneously in the event of a collision. The high - precision manufacturing capabilities of injection molding guarantee that the connectors meet the strict safety standards required by the automotive industry. Additionally, connectors in the lighting systems, infotainment systems, and electric vehicle charging ports are often produced through injection molding. They need to be resistant to vibration, temperature variations, and moisture, and the material diversity and design flexibility of injection molding enable the production of connectors that can withstand these harsh automotive environments.

In Consumer Electronics

Consumer electronics is another industry where connector injection molding is widely applied. Take smartphones as an example. Inside a smartphone, there are numerous connectors, such as those for the battery, camera, display, and various sensors. These connectors are small in size but require high - precision manufacturing to ensure reliable electrical connections. The high - speed data transfer between components like the processor and the memory also depends on the quality of the connectors. With the continuous miniaturization of consumer electronics, injection - molded connectors can be designed to be extremely small while still maintaining excellent performance.

In laptops and desktop computers, connectors are used for connecting the motherboard to components like the hard drive, graphics card, and power supply. The design flexibility of injection molding allows for the creation of connectors with unique shapes and features to fit the compact and complex internal structures of these devices. For instance, some connectors may have integrated locking mechanisms to prevent accidental disconnection during normal use, and injection molding can easily produce such complex designs.

In the Medical Field

The medical field has extremely high requirements for the precision and reliability of connectors. In diagnostic equipment like MRI machines, CT scanners, and ultrasound devices, connectors are used to transmit large amounts of data and electrical signals. For example, in an MRI machine, the connectors need to ensure the accurate transmission of high - frequency signals between the magnet coils and the control system. Any signal interference or connection failure could lead to inaccurate diagnostic results, which could have serious consequences for patients.

In surgical instruments and life - support systems, the reliability of connectors is even more critical. For example, in a heart - lung machine used during open - heart surgeries, the connectors must maintain a stable connection under high - pressure and high - temperature conditions. The biocompatibility of the materials used in injection - molded connectors is also of utmost importance in medical applications. Materials like medical - grade silicone and polyether ether ketone (PEEK) are often used as they are non - toxic and do not cause adverse reactions when in contact with the human body.

In Aerospace and Aviation

Aerospace and aviation are industries where the performance requirements for materials and components are extremely demanding. Injection - molded connectors are used in aircraft avionics systems, satellite communication equipment, and rocket guidance systems. These connectors need to withstand extreme temperatures, high - altitude radiation, and mechanical vibrations.

For example, in an aircraft's flight control system, the connectors must ensure reliable signal transmission between the control panels and the actuators that control the aircraft's wings, rudders, and engines. The lightweight nature of injection - molded connectors made from high - performance plastics is also an advantage in aerospace applications as it helps to reduce the overall weight of the aircraft or spacecraft, improving fuel efficiency or increasing payload capacity. The high - precision manufacturing capabilities of injection molding ensure that the connectors meet the strict quality standards of the aerospace industry, where even the smallest defect can have catastrophic consequences.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology highly values connector injection molding. With rich experience in custom - based services, we have mastered advanced techniques in this field. Our state - of - the - art equipment and skilled workforce enable us to create custom connector molds with precision, ensuring high - quality production. We are proficient in handling various materials, meeting diverse client requirements. Whether it's for a small - scale prototype or large - scale production, Yigu Technology can provide efficient and reliable solutions for connector injection molding, ensuring products that are both functional and cost - effective.

FAQ

What are the common materials used in connector injection molding?

Common materials include acrylonitrile - butadiene - styrene (ABS), known for good impact resistance, surface finish, and ease of processing. Polycarbonate (PC) offers high strength, heat resistance, and excellent electrical insulation. Liquid silicone rubber (LSR) is used for high - flexibility and biocompatibility applications, such as in medical devices.

How to ensure the quality of connector injection molding products?

To ensure quality, start with a well - designed mold. A precision - engineered mold with proper venting and cooling channels is crucial. Select high - quality raw materials from reliable suppliers, and conduct strict quality checks on the materials before production. During the production process, closely monitor and control parameters like injection pressure, temperature, and cooling time. Implement in - line quality inspection, such as using sensors to detect any irregularities in the injection process, and perform post - production inspections, including dimensional measurements and functional testing.

Can connector injection molding be used for small - batch production?

Connector injection molding can be used for small - batch production, but it has some considerations. The initial mold cost is a significant factor. Since the cost of mold manufacturing is relatively high, for small - batch production, the unit cost per part may be higher compared to mass production. However, if the design requires high precision and complex shapes, injection molding can still be a viable option. Some manufacturers may also offer mold - sharing or using modular molds for small - batch production to reduce costs. Additionally, rapid prototyping techniques combined with injection molding can speed up the production process for small - batch orders.