Understanding Auto Parts Mould

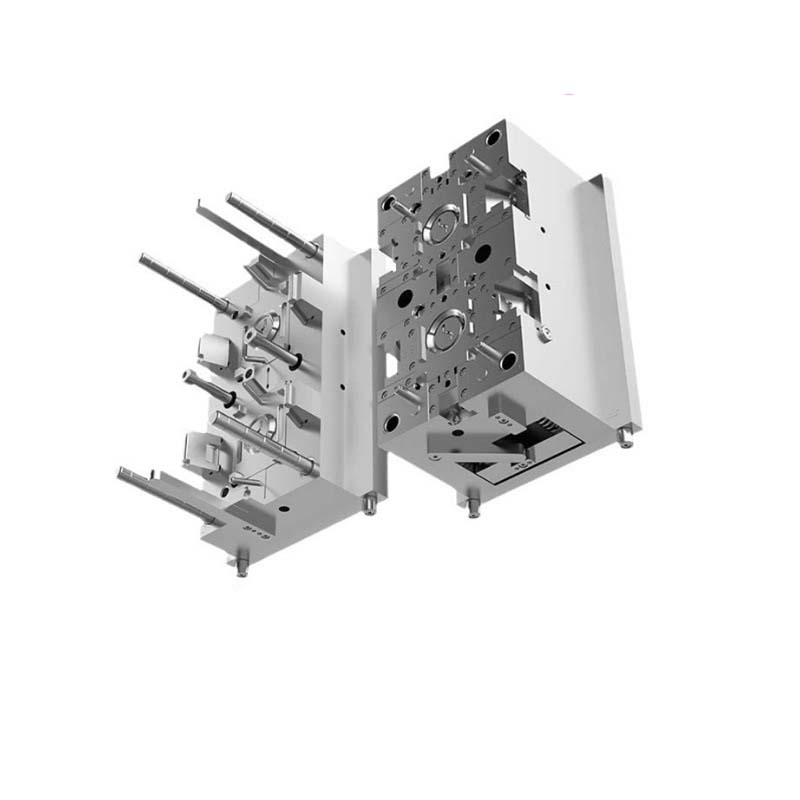

Auto parts moulds are the unsung heroes behind the scenes of the automotive industry. They are the tools that shape the various components of your car, from the smallest interior knobs to the large body panels. But why are they so crucial?

The Backbone of Automotive Production

First and foremost, the quality of auto parts moulds directly impacts the quality of the car components. High - precision moulds can produce parts with exact dimensions, ensuring a perfect fit during assembly. For example, a well - crafted mould for a car door panel will result in a panel that aligns seamlessly with the car's body, reducing air leaks and improving aerodynamics. According to industry statistics, cars with components made from high - quality moulds have a 30% lower chance of developing rattles or vibrations during operation, which significantly improves the driving experience.

Safety at Stake

Safety is another area where auto parts moulds play a critical role. Consider components like brake calipers. A mould that is not up to standard may produce calipers with inconsistent thickness or shape. This could lead to uneven braking force distribution, potentially causing the car to pull to one side during braking, a serious safety hazard. In fact, research shows that about 15% of brake - related accidents can be traced back to faulty components that were likely the result of poor - quality moulds.

Cost - Efficiency in the Long Run

Investing in a good auto parts mould can also save costs in the long term. While high - quality moulds may have a higher upfront cost, they are more durable and can produce a larger number of parts before needing replacement. For instance, a premium - grade injection mould for plastic interior parts can produce up to 500,000 parts, compared to a lower - quality mould that might only manage 100,000 parts. This means fewer production stoppages for mould replacement and lower overall production costs per part.

Given their importance, choosing the best auto parts mould for your car is not a decision to be taken lightly. In the following sections, we will explore the key factors you need to consider when making this choice.

Key Factors to Consider When Choosing

Material Quality

The material of an auto parts mould is fundamental to its performance. Common materials include carbon steel, stainless steel, and alloy steel.

Carbon Steel Moulds

Carbon steel is a popular choice due to its relatively low cost. It has good machinability, which means it can be easily shaped into the desired mould form. However, its durability might be a concern in some applications. For example, in high - volume production of non - critical plastic auto parts like interior trim pieces, carbon steel moulds can be a cost - effective option. They can produce a significant number of parts, say around 50,000 - 100,000 units, before showing signs of wear. But in an environment with high humidity or when dealing with corrosive substances, carbon steel may rust over time, reducing the precision of the mould.

Stainless Steel Moulds

Stainless steel, on the other hand, offers excellent corrosion resistance. This makes it ideal for moulds that will be exposed to harsh conditions, such as those used in the production of auto parts for marine - based vehicles or parts that need to withstand chemical exposure. Although stainless steel is more expensive than carbon steel, its longer lifespan can offset the higher initial cost. For instance, a stainless - steel mould used in producing engine components that are in contact with various fluids can last up to 300,000 - 500,000 production cycles, far more than a comparable carbon - steel mould in the same application.

Alloy Steel Moulds

Alloy steel combines the advantages of different metals, offering enhanced strength, hardness, and heat resistance. These moulds are suitable for high - stress applications, like die - casting moulds for producing complex and high - strength auto parts such as transmission gears. They can endure the high pressures and temperatures involved in the die - casting process, ensuring consistent part quality over a long production run of perhaps 200,000 - 400,000 parts.

Precision and Tolerance

Precision and tolerance are two terms that are often used in the context of auto parts moulds, and they are of utmost importance.

Defining Precision and Tolerance

Precision refers to how closely a mould can reproduce the exact shape and dimensions of the designed auto part. Tolerance, on the other hand, is the acceptable deviation from the ideal dimensions. For example, if a car door handle is designed to have a length of 150 mm, a well - made mould might have a tolerance of ±0.1 mm. This means that the actual length of the door handles produced by the mould can be anywhere from 149.9 mm to 150.1 mm and still be considered acceptable.

The Significance for Auto Parts Quality and Assembly

High - precision moulds with tight tolerances are crucial for ensuring the quality and proper assembly of auto parts. In the case of engine components, such as pistons, even a slight deviation in size can lead to engine inefficiencies, increased fuel consumption, and potentially engine failure. Research shows that engines with components produced from moulds with a tolerance of more than ±0.2 mm are 25% more likely to experience performance issues compared to those with components from moulds with a tolerance of ±0.1 mm or less.

For the assembly process, parts produced from precise moulds fit together seamlessly. This reduces the need for additional machining or adjustment during assembly, saving both time and cost. A study in the automotive industry found that cars assembled with parts from high - precision moulds had 10% fewer assembly - related defects, leading to a more reliable final product.

Manufacturer's Reputation

When choosing an auto parts mould, the reputation of the manufacturer should not be overlooked.

Checking Reviews and Testimonials

One way to gauge a manufacturer's reputation is by looking at online reviews and testimonials from previous customers. A manufacturer with a high number of positive reviews is more likely to produce reliable moulds. For example, if a mould manufacturer has an average rating of 4.5 out of 5 stars on a popular business review platform, with comments praising the quality of their moulds and their excellent customer service, it's a good sign. On the other hand, multiple negative reviews about mould failures or poor after - sales support should raise red flags.

Cost - Benefit Analysis

While the cost of an auto parts mould is an important factor, it should not be the sole determinant. A comprehensive cost - benefit analysis is necessary.

The Relationship between Price, Quality, and Lifespan

A cheaper mould may seem attractive at first glance, but it could end up costing more in the long run. Low - cost moulds may have shorter lifespans and produce parts of lower quality. For example, a mould that costs \(5,000 but can only produce 50,000 parts before needing replacement, compared to a \)10,000 mould that can produce 200,000 parts. If the cost per part produced is calculated, the more expensive mould may actually be more cost - effective in the long term.

Maintenance Costs and Their Impact

Maintenance costs also need to be considered. Some moulds may require frequent maintenance, which can add to the overall cost. High - quality moulds, although more expensive initially, may have lower maintenance requirements. For example, a mould made from high - grade steel may need only an annual maintenance check, while a lower - quality mould may need monthly maintenance, including repairs and replacements of worn - out parts.

Calculating the Total Cost of Ownership

To conduct a proper cost - benefit analysis, calculate the total cost of ownership. This includes the initial purchase price, maintenance costs, and the cost of any production losses due to mould failures or downtime. For example, if a mould fails during production and causes a production halt for a day, costing the company $10,000 in lost productivity, this cost should be factored into the total cost of ownership. By considering all these aspects, you can make a more informed decision and choose the auto parts mould that offers the best value for your specific needs.

Types of Auto Parts Moulds and Their Differences

Auto parts moulds come in various types, each designed to meet specific manufacturing requirements. Here are some common types and their key differences:

| Type of Mould | Material | Characteristic Features | Applications |

| Injection Mould for Plastic Parts (e.g., Interior Trim Pieces) | Usually made of steel alloys (such as P20 steel for general - purpose use). P20 steel offers a good balance of machinability, hardness, and cost - effectiveness | High - precision moulds can produce parts with smooth surfaces and tight tolerances, often within ±0.05 - 0.1 mm. They can create complex shapes with fine details. For example, the mould for a car dashboard can have intricate patterns and precise cut - outs for various controls. Injection moulding allows for high - volume production, with the ability to produce thousands of parts per day. | Widely used for interior components like dashboards, door panels, and cup holders. These parts need to have a good aesthetic appearance and fit well within the car's interior space. |

| Die - Casting Mould for Metal Parts (e.g., Engine Blocks, Transmission Housings) | Made from high - strength hot - work tool steels, such as H13 steel. H13 steel has excellent heat resistance, toughness, and wear resistance | Capable of withstanding high pressures (up to 100 - 150 MPa) and high temperatures (around 600 - 800°C during the die - casting process). It can produce parts with high dimensional accuracy, typically with tolerances of ±0.1 - 0.3 mm. Die - casting moulds can create parts with complex internal structures, like the internal cooling channels in an engine block. | Ideal for manufacturing engine components, transmission parts, and other high - strength metal parts that need to withstand heavy loads and high - stress conditions. |

| Compression Mould for Rubber Parts (e.g., Seals, Gaskets) | Moulds are often made of steel or aluminum. Aluminum is sometimes used for lower - volume production due to its lower cost and good thermal conductivity, while steel is more suitable for high - volume production due to its higher durability | Can handle the unique properties of rubber materials, such as their elasticity and compressibility. The moulds are designed to apply pressure and heat to shape the rubber into the desired form. Compression moulds can produce parts with relatively large cross - sectional areas and simple shapes. For example, a large - diameter rubber gasket can be easily produced using a compression mould. | Used for manufacturing rubber components that are essential for sealing, vibration isolation, and shock absorption in cars, such as door seals, engine gaskets, and suspension bushings. |

| Blow Mould for Hollow Plastic Parts (e.g., Fuel Tanks) | Constructed from steel or aluminum alloys. Steel is preferred for high - volume production of large - sized parts like fuel tanks due to its strength and durability | Allows for the production of hollow, thin - walled plastic parts. The process involves inflating a heated plastic tube (parison) inside a mould cavity to form the final shape. Blow moulds can create parts with varying wall thicknesses to meet different strength and weight requirements. For example, a fuel tank made by blow moulding can have thicker walls in areas that are more likely to be impacted. | Mainly used for manufacturing large - scale hollow plastic components, such as fuel tanks, which need to have a certain capacity and strength while being lightweight. |

Understanding these differences is crucial when choosing the right auto parts mould for your specific car component production needs. Each type of mould has its own advantages and is best - suited for particular applications, depending on factors such as the material of the part, the complexity of the design, and the required production volume.

Yigu Technology's Viewpoint

As a non - standard plastic and metal products custom supplier, Yigu Technology emphasizes several key points in choosing auto parts moulds. First, material quality is vital. High - quality materials like top - grade alloy steel ensure the mould's durability and the precision of the parts produced. Second, precision and tolerance directly impact the quality of auto parts. We always strive for the tightest tolerances in our mould - making process. Additionally, the experience of the mould supplier matters. Our years of experience in custom - making moulds allow us to understand various requirements and provide tailored solutions. Yigu Technology is committed to providing high - quality, customized auto parts moulds and excellent after - sales service to meet the diverse needs of our customers in the automotive industry.

FAQ

What is the most common material for auto parts moulds?

The most common materials for auto parts moulds are steel and aluminum alloy. Steel, such as carbon steel, stainless steel, and alloy steel, is popular due to its high strength, good machinability, and wear - resistance. Carbon steel is cost - effective for non - critical parts production, stainless steel offers excellent corrosion resistance, and alloy steel provides enhanced strength and heat resistance. Aluminum alloy, on the other hand, is lightweight and has good thermal conductivity, making it suitable for some specific applications where weight reduction is crucial.

How can I tell if a mould is of high quality?

You can judge the quality of a mould from several aspects. Visually, the surface should be smooth without obvious scratches, dents, or pores. Measure the key dimensions of the mould with high - precision measuring tools like calipers and micrometers to ensure they meet the design requirements. High - quality mould materials usually have appropriate hardness and toughness, which can be evaluated through hardness tests and material analysis. A well - designed mould structure should ensure even stress distribution during operation, reducing deformation and wear. Additionally, check the production process; advanced processing techniques like CNC machining can guarantee higher precision and consistency.

Is it better to choose a domestic or overseas mould supplier?

Both domestic and overseas mould suppliers have their own advantages and disadvantages. Domestic suppliers may offer shorter lead times, easier communication due to the same language and time zone, and potentially lower costs in some cases. They can also provide more convenient after - sales service. Overseas suppliers, especially those from developed countries, may have more advanced technology and rich experience, which can ensure high - quality moulds. However, they may be more expensive, and there could be communication barriers and longer shipping times. It's best to comprehensively consider your specific needs, budget, and quality requirements before making a decision.