What is Ejector Rod Injection Molding?

Ejector rod injection molding is a specialized manufacturing process within the realm of injection molding, which is widely used to produce a variety of plastic and some metal components. The process is particularly focused on creating ejector rods, which are crucial parts in molds for the injection molding process itself.

The fundamental principle involves injecting a molten material, typically a thermoplastic polymer or in some cases, a metal alloy in metal injection molding (MIM), into a precisely designed mold cavity. For ejector rod injection molding, the mold cavity is shaped to form the specific geometry of the ejector rod, which usually has a cylindrical shape with specific dimensions and may include features like grooves or threaded ends depending on its application.

Once the molten material is injected into the mold cavity under high pressure, it begins to cool and solidify. This cooling process is carefully regulated to ensure uniform solidification and the development of the desired material properties in the ejector rod. The cooling time depends on various factors such as the material used, the thickness of the rod, and the cooling system of the mold. For example, if a fast - cooling material like polyethylene is used for a small - diameter ejector rod, the cooling time might be relatively short, perhaps on the order of a few seconds to a minute. In contrast, for a metal alloy ejector rod with a larger cross - section, the cooling time could be several minutes.

After the material has solidified, the mold is opened, and the newly formed ejector rod is ejected from the mold. This is typically done using a mechanical ejection system within the mold, which may involve ejector pins or other mechanisms that push the rod out of the cavity. The ejected rod then undergoes further post - processing steps such as trimming any excess material (flash), polishing for better surface finish if required, and quality inspection.

This process offers several advantages. It allows for high - precision manufacturing, enabling the production of ejector rods with tight tolerances. For instance, in high - end injection molds used in the automotive or electronics industries, ejector rods need to have very accurate dimensions, and injection molding can achieve tolerances as low as ±0.01 mm. Additionally, it is a highly efficient mass - production method. Once the mold is set up, large quantities of ejector rods can be produced in a relatively short time, making it cost - effective for industries with high - volume demands.

Key Components and Their Functions

Mold Structure

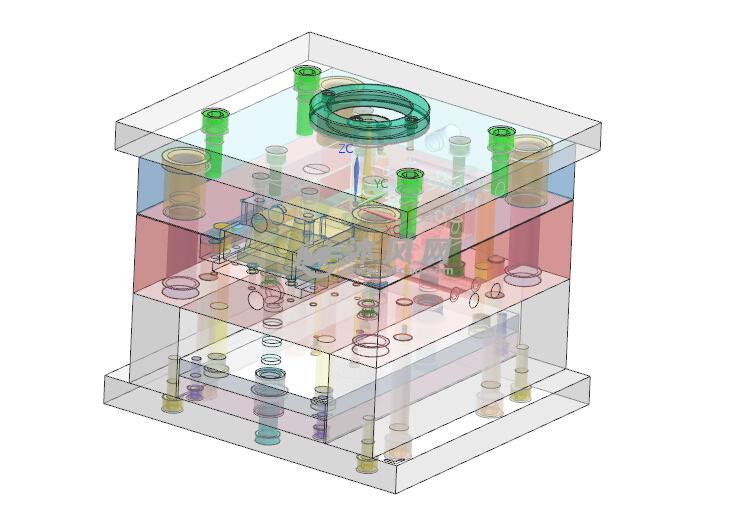

The mold is the heart of the ejector rod injection molding process, as it determines the final shape and dimensions of the ejector rod. A typical mold for ejector rod injection molding consists of several key components:

- Cavity: This is the hollow space within the mold that gives the ejector rod its shape. The cavity is precisely machined to the desired specifications of the ejector rod, including its diameter, length, and any surface features. For example, if the ejector rod has a threaded end, the cavity will be designed with the corresponding internal threads. Any imperfections in the cavity can lead to defects in the final product, such as surface roughness or incorrect dimensions.

- Core: The core is the part of the mold that forms the inner or central portion of the ejector rod. In the case of a solid ejector rod, the core may be a simple cylindrical shape. However, for more complex ejector rods with internal channels or features, the core will be designed to create those specific geometries. The core and cavity work in tandem to enclose the molten material during injection and ensure proper solidification.

- Slides: Slides are used in molds when the ejector rod has side features or undercuts that cannot be easily removed by simple ejection. Slides can move laterally within the mold to create these complex features. For instance, if the ejector rod has a groove along its side, a slide mechanism can be used to form the groove during injection and then retract to allow for the ejection of the solidified rod.

Injection System

The injection system is responsible for heating, melting, and injecting the plastic material into the mold. It consists of the following main components:

- Screw: The screw is a crucial part of the injection system. It rotates within the barrel and serves multiple functions. As it rotates, the screw conveys the plastic pellets from the hopper towards the front of the barrel. During this movement, the screw also compresses and shears the plastic, generating heat through friction. This heat, combined with the external heating elements on the barrel, melts the plastic. The pitch and diameter of the screw are carefully designed based on the type of plastic material being processed and the required injection volume. For example, a larger - pitched screw may be used for materials that are easier to melt and convey, while a smaller - pitched screw may be more suitable for high - viscosity plastics.

- Barrel: The barrel houses the screw and provides a chamber for the plastic to be heated and melted. It is equipped with heating bands that can be adjusted to different temperature zones. The temperature profile along the barrel is carefully controlled to ensure that the plastic is uniformly melted and ready for injection. The inner surface of the barrel needs to be smooth to minimize friction and prevent material degradation during the plastic's movement.

- Nozzle: The nozzle is the end - point of the injection system, where the molten plastic exits the barrel and enters the mold. It has a small orifice that can be adjusted to control the flow rate of the plastic into the mold. The nozzle also needs to be able to seal tightly against the mold's sprue bushing to prevent any leakage of the molten plastic during injection.

Ejection Mechanism

The ejection mechanism plays a vital role in removing the solidified ejector rod from the mold after the cooling phase. Key components of the ejection mechanism include:

- Ejector Pins: These are slender rods that are placed in strategic locations within the mold. When the mold opens, hydraulic or mechanical force is applied to the ejector pins, causing them to push against the ejector rod. The ejector pins are designed to have a small contact area with the ejector rod to prevent damage to the rod's surface while providing enough force to eject it from the mold. For example, if the ejector rod has a smooth cylindrical surface, the ejector pins may be placed evenly around the circumference of the rod's end - face.

- Ejector Rods: Ejector rods are larger - diameter rods that transfer the force from the injection molding machine's ejection system to the ejector pins. They are usually made of high - strength steel to withstand the forces involved in the ejection process. Ejector rods ensure that the ejection force is evenly distributed among the ejector pins, allowing for a smooth and efficient ejection of the ejector rod from the mold.

Process Steps in Detail

Material Preparation

Before the injection molding process begins, the plastic material, usually in the form of pellets or powder, undergoes several important pre - treatment steps. One of the crucial steps is drying. Many thermoplastic materials, such as nylon, are hygroscopic, meaning they absorb moisture from the air. If the material contains excessive moisture, it can cause defects in the final product. For example, when the molten plastic with moisture is injected into the mold, the moisture turns into steam during the high - temperature process, creating voids or bubbles in the ejector rod. To prevent this, the plastic pellets are dried in a specialized dryer. The drying temperature and time vary depending on the material. Nylon may need to be dried at around 80 - 100°C for 2 - 4 hours.

In addition to drying, additives may be mixed with the plastic material. Additives can serve various purposes. For instance, colorants are added to give the ejector rod a specific color. UV stabilizers are used if the ejector rod will be exposed to sunlight, as they protect the plastic from degradation caused by ultraviolet rays. Flame retardants are added when the end - use application requires fire - resistance properties. The proper mixing of additives is essential to ensure their uniform distribution throughout the plastic matrix, which directly impacts the quality and performance of the final ejector rod.

Heating and Melting

The dried plastic material is fed into the injection molding machine's barrel. Inside the barrel, a rotating screw plays a key role in the heating and melting process. As the screw rotates, it conveys the plastic pellets from the hopper towards the front of the barrel. During this movement, the plastic is subjected to both external heat from the heating bands wrapped around the barrel and internal heat generated by the shear forces created by the rotation of the screw.

The temperature of the barrel is divided into different zones. The rear zone, where the plastic pellets enter, is usually set at a lower temperature, around 150 - 180°C for common plastics like polyethylene. As the plastic moves forward towards the front of the barrel, the temperature gradually increases. The front zone, near the nozzle, may have a temperature of 200 - 250°C for polyethylene. This temperature gradient ensures that the plastic is gradually and uniformly melted.

Temperature control is of utmost importance. If the temperature is too low, the plastic may not melt completely, leading to uneven injection and defects in the ejector rod such as short - shots (incomplete filling of the mold cavity). On the other hand, if the temperature is too high, the plastic can degrade, losing its mechanical properties and potentially causing discoloration or charring. For example, some heat - sensitive plastics like certain grades of polycarbonate can start to degrade if the temperature exceeds their recommended processing range by more than 20 - 30°C.

Injection

Once the plastic is fully melted and in a homogeneous, viscous state, it is ready to be injected into the mold cavity. A high - pressure hydraulic system is used to push the screw forward, forcing the molten plastic through the nozzle and into the mold. The injection pressure can range from 50 - 200 MPa, depending on factors such as the complexity of the mold design, the viscosity of the plastic material, and the size of the ejector rod being produced.

Injection pressure has a significant impact on the product 成型. If the pressure is too low, the molten plastic may not be able to fill the entire mold cavity, resulting in a defective ejector rod with missing parts or under - filled sections. Conversely, if the pressure is too high, it can cause flash (excess plastic flowing into areas where it shouldn't) around the edges of the ejector rod, or even damage the mold due to the excessive force exerted.

The injection speed also plays a crucial role. A fast injection speed can help to quickly fill the mold cavity, reducing the risk of premature cooling and solidification of the plastic. However, if the speed is too fast, it can cause air to be trapped inside the mold cavity, creating voids or porosity in the ejector rod. A slow injection speed, on the other hand, may lead to long cycle times and potential non - uniform filling of the mold. For a small - diameter ejector rod made of a low - viscosity plastic like polyethylene, an injection speed of 50 - 100 mm/s might be appropriate, while for a larger and more complex ejector rod made of a high - viscosity plastic like polypropylene copolymer, a slower injection speed of 20 - 50 mm/s could be required.

Cooling and Solidification

After the mold cavity is filled with the molten plastic, the cooling process begins. Cooling is essential for the plastic to solidify and take on the shape of the ejector rod. The mold is usually equipped with a cooling system, which can use either water or air as the cooling medium. Water is a more efficient cooling medium as it has a higher heat - transfer coefficient compared to air.

The cooling time is a critical parameter. It depends on factors such as the thickness of the ejector rod, the material used, and the cooling efficiency of the mold. For a thin - walled ejector rod made of a fast - cooling plastic like polystyrene, the cooling time may be as short as 5 - 10 seconds. In contrast, for a thick - walled ejector rod made of a material with a high melting point and slow - cooling characteristics, such as some engineering plastics like polyetheretherketone (PEEK), the cooling time could be several minutes.

If the cooling time is too short, the plastic may not solidify completely, and the ejector rod may deform when it is ejected from the mold. On the other hand, if the cooling time is too long, it can increase the production cycle time and reduce productivity. The temperature of the cooling medium also affects the quality of the ejector rod. If the cooling medium is too cold, it can cause uneven cooling, leading to internal stresses in the ejector rod, which may result in warping or cracking during or after ejection.

Ejection

Once the plastic has solidified and cooled to a sufficient extent, the mold is opened, and the ejection mechanism comes into action. The ejection mechanism typically consists of ejector pins and ejector rods. The ejector pins are small, slender rods that are placed at strategic locations within the mold, usually at the end - face or along the sides of the ejector rod cavity.

When the mold opens, hydraulic or mechanical force is applied to the ejector rods, which in turn transfer the force to the ejector pins. The ejector pins then push against the ejector rod, forcing it out of the mold cavity. To avoid damaging the ejector rod during ejection, the ejector pins should have a proper contact area and be evenly distributed. If the ejector pins are too small or not properly positioned, they can cause indentations or marks on the surface of the ejector rod.

The ejection force also needs to be carefully controlled. If the force is too low, the ejector rod may not be fully ejected from the mold, and additional manual intervention may be required. If the force is too high, it can cause the ejector rod to break or deform. For example, for a small - diameter ejector rod made of a relatively brittle plastic, the ejection force may need to be precisely calibrated to ensure a smooth and damage - free ejection.

Yigu Technology's Perspective

As a non - standard plastic metal products custom supplier, Yigu Technology has in - depth experience in ejector rod injection molding. Our expertise lies in understanding the unique requirements of each customer's ejector rod needs.

We possess advanced injection molding equipment and a team of skilled engineers. This enables us to handle complex mold designs for ejector rods. For example, when customers require ejector rods with special geometries or tight tolerances, our engineers can optimize the mold design to ensure high - precision production.

In terms of material selection, we have a wide range of plastic and metal materials at our disposal. Whether it's high - strength engineering plastics for general applications or heat - resistant metal alloys for high - temperature environments, we can recommend and use the most suitable materials.

Moreover, our quality control system ensures that every ejector rod leaving our factory meets the highest standards. We conduct strict inspections at every stage of the production process, from material incoming inspection to the final product inspection, to provide customers with reliable ejector rods.