Understanding the Importance of a Right Injection Mold Manufacturer

Selecting the right injection mold manufacturer is far from a trivial decision; it's a cornerstone of success in manufacturing. This choice has a profound impact on three critical aspects: product quality, cost control, and production efficiency.

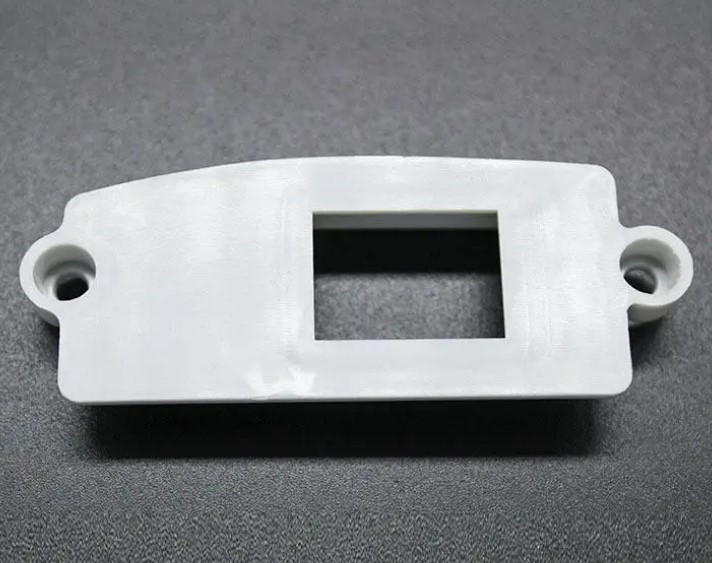

Product Quality: The quality of an injection - molded product is inextricably linked to the expertise of the mold manufacturer. High - quality molds, crafted by experienced manufacturers, ensure consistent product dimensions. For instance, in the production of medical device components, precision is non - negotiable. A deviation of even a fraction of a millimeter can render the product unusable or, worse, dangerous. A reliable injection mold manufacturer will use advanced design software like CAD (Computer - Aided Design) and high - precision manufacturing equipment such as CNC (Computer Numerical Control) machines to achieve tight tolerances. They also implement strict quality control measures at every stage, from raw material inspection to final product testing. This attention to detail results in products with smooth surfaces, accurate shapes, and reliable functionality, enhancing the overall brand reputation.

Cost Control: An apt injection mold manufacturer can significantly influence cost - effectiveness. In the short term, a lower - priced mold might seem appealing, but it could lead to higher costs down the line. For Yigu Technology example, a poorly made mold may require frequent repairs or replacements, increasing maintenance expenses. On the other hand, a well - designed and - constructed mold from a reputable manufacturer may have a higher upfront cost but can produce a large number of parts with minimal defects. This reduces the cost per unit by minimizing waste and rework. Additionally, an experienced manufacturer can offer advice on material selection, helping you choose the most cost - effective yet suitable materials for your product, further cutting down costs.

Production Efficiency: The production efficiency of your manufacturing process is highly dependent on the injection mold manufacturer. A manufacturer with high - speed and reliable equipment can shorten the cycle time of mold production. For example, modern injection molding machines can complete a cycle in a matter of seconds, enabling high - volume production. Moreover, a well - organized production schedule and effective communication from the manufacturer ensure timely delivery of molds. This means you can start your production on time, meet market demands promptly, and avoid costly production delays. In a competitive market, every day of production delay can translate into lost sales opportunities and revenue.

Key Factors to Consider

Experience and Expertise

Years in the Industry

The number of years an injection mold manufacturer has been in business is a crucial indicator of its stability and experience. A manufacturer with a long - standing presence, say 10 years or more, has likely weathered various market challenges and technological shifts. They have had the opportunity to refine their processes, build a reliable supply chain, and accumulate a wealth of knowledge in mold design and production. For Yigu Technology example, a 15 - year - old manufacturer may have dealt with hundreds of different mold projects, ranging from simple to highly complex designs. This extensive experience enables them to anticipate potential issues during the design phase and find effective solutions quickly.

In contrast, a relatively new manufacturer, perhaps one in operation for less than 3 years, may still be in the learning curve. While they may bring fresh ideas and new - age technologies, they might lack the depth of experience in handling large - scale projects or complex mold designs. However, new manufacturers can also be innovative and offer more competitive pricing as they strive to establish themselves in the market.

Range of Services Offered

A manufacturer that provides a full - range of services, including mold design, mold manufacturing, and injection molding, offers significant advantages. This one - stop - shop approach simplifies the manufacturing process for clients. For instance, if a client has an idea for a new plastic product, they can work with the manufacturer from the initial concept design stage. The in - house design team can use advanced CAD/CAM software to create a detailed mold design. Then, the same manufacturer can produce the mold using high - precision machinery and finally carry out the injection molding process. This seamless transition between different stages reduces communication barriers and potential errors that could occur when multiple external suppliers are involved.

On the other hand, a manufacturer that only offers a single service, such as just mold manufacturing, may limit the client's options. The client would then need to source other services from different providers, which can lead to coordination difficulties, longer lead times, and potentially higher costs.

Industry Specializations

Injection mold manufacturers often specialize in specific industries, such as automotive, medical, or electronics. Each industry has its own unique requirements for molds.

Automotive Industry: Molds for automotive parts need to be highly durable to withstand high - volume production. For example, molds for car bumpers or interior components must be able to produce thousands or even millions of parts without significant wear and tear. They also need to meet strict safety and aesthetic standards. The materials used in automotive molds are often high - grade steels that can handle the large injection pressures required for molding large - sized parts.

Medical Industry: In the medical field, precision and cleanliness are of utmost importance. Molds for medical devices, like syringes or surgical instrument components, must have extremely tight tolerances to ensure the proper functionality of the final product. The mold surfaces need to be highly polished to prevent any particle contamination. Additionally, the materials used in medical molds must be biocompatible and meet strict regulatory standards such as ISO 13485 for medical device quality management.

Electronics Industry: Molds for electronic components, such as smartphone casings or circuit board connectors, often require high - precision manufacturing to accommodate the miniaturization trend in electronics. They need to be able to produce parts with very fine details and tight tolerances to ensure proper fit and functionality within electronic devices.

Quality Assurance

Certifications and Standards

Certifications play a vital role in assessing the quality of an injection mold manufacturer. Standards like ISO 9001:2015 are internationally recognized for quality management systems. A manufacturer with ISO 9001 certification has demonstrated that it has established effective quality control processes, from raw material procurement to product delivery. It ensures that the company follows a set of standardized procedures, which in turn leads to consistent product quality.

For the automotive industry, IATF 16949 certification is highly valued. This standard is based on ISO 9001 but has additional requirements specific to the automotive sector. It focuses on aspects such as defect prevention, reduction of waste, and continuous improvement in the automotive supply chain. A manufacturer with IATF 16949 certification is more likely to meet the stringent quality and delivery requirements of automotive OEMs (Original Equipment Manufacturers).

Quality Control Processes

A reliable injection mold manufacturer has a comprehensive quality control process. It starts with the inspection of raw materials. For Yigu Technology example, the steel used for mold making is carefully examined for its chemical composition and mechanical properties. Any deviation from the specified standards can lead to mold failures during production.

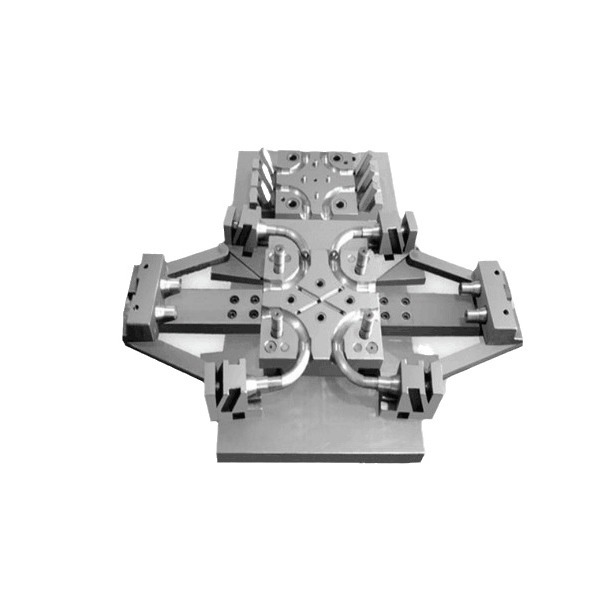

During the mold manufacturing process, multiple inspections are carried out. CNC - machined parts are checked for dimensional accuracy using precision measuring tools such as coordinate measuring machines (CMMs). After the mold is assembled, it undergoes a trial run to check for any potential issues like improper filling, flashing, or warping.

For the final injection - molded products, a sampling inspection is usually done. Statistical process control (SPC) techniques are often employed to monitor the production process continuously. This involves collecting and analyzing data on key quality characteristics, such as part dimensions and weight, to detect any trends or variations that could indicate a problem in the production process.

Production Capacity and Equipment

Machinery and Technology

Advanced machinery is a key factor in the efficiency and quality of injection mold production. High - precision CNC machines are capable of achieving tight tolerances, often within micrometers. They can accurately mill, drill, and cut complex shapes in the mold components. For example, a five - axis CNC machine can work on multiple sides of a mold part without the need for re - positioning, reducing errors and improving the overall precision.

Electrical discharge machining (EDM) machines are also crucial, especially for creating intricate details in molds. They use electrical discharges to erode the material and can produce features that are difficult to achieve with traditional machining methods. EDM is often used for making molds with fine internal channels, sharp corners, or complex cavities.

Production Volume Capabilities

Manufacturers come in different sizes with varying production volume capabilities. A large - scale manufacturer may have dozens of high - capacity injection molding machines and can handle high - volume orders, say producing hundreds of thousands or even millions of parts per month. This makes them suitable for large - scale consumer product manufacturers or automotive companies with high - volume production needs.

Small - to - medium - sized manufacturers, on the other hand, may have a more limited number of machines and are better suited for low - to - medium - volume production runs. They can be more flexible in handling smaller orders or customized projects, which may require more attention to detail and shorter lead times. When choosing a manufacturer, it's important to match your production volume requirements with the manufacturer's capabilities to ensure cost - effectiveness and timely delivery.

Cost - Effectiveness

Pricing Structure

The pricing of injection molds is composed of several factors. Material costs form a significant part, especially for high - quality steels used in mold making. For example, premium - grade tool steels can be much more expensive than standard steels but offer better durability and performance.

Labor costs also contribute to the overall price. Skilled mold designers, machinists, and technicians command higher wages. Their expertise is essential for ensuring the quality of the mold, but it also adds to the cost. Equipment depreciation is another factor. High - end CNC machines and EDM equipment are expensive to purchase and maintain, and these costs are spread over the molds produced.

When negotiating prices with a manufacturer, it's important to understand these cost components. You can try to find a balance between quality and cost by discussing alternative materials or production methods that may reduce costs without sacrificing too much on quality.

Hidden Costs

It's crucial to be aware of potential hidden costs. Shipping costs can be significant, especially if the manufacturer is located far away. For large and heavy molds, international shipping fees can add a substantial amount to the overall cost.

After - sales service costs should also be considered. If the mold requires repairs or maintenance during its lifespan, the manufacturer's charges for these services can vary. Some manufacturers may offer a limited warranty period, but after that, any repairs could come at a high cost. By being aware of these potential hidden costs upfront, you can avoid budget overruns and make a more informed decision when choosing a manufacturer.

Yigu Technology's Perspective

As a non - standard plastic metal products custom Supplier, Yigu Technology highly values quality control. We understand that every detail in the mold - making process is crucial for the final product's quality. Our in - house quality inspection team uses advanced testing equipment to conduct strict inspections at each production stage, from raw material inspection to the finished mold, to ensure that the molds we provide meet the highest quality standards.

Customization is also at the core of our service concept. We believe that each client has unique requirements. Therefore, we work closely with clients from the initial design stage, providing personalized solutions. Our experienced engineers are proficient in using a variety of design software, which enables us to transform clients' ideas into practical and efficient mold designs. By offering customized services, we aim to help clients achieve their specific production goals and gain a competitive edge in the market.

FAQs

What is the typical lead time for an injection mold project in China?

The lead time for an injection mold project in China can vary significantly depending on several factors. For relatively simple mold designs with standard sizes and common materials, the lead time might be as short as 3 - 4 weeks. However, for complex molds with high - precision requirements, such as those for medical or aerospace components, it can take 8 - 12 weeks or even longer.

The complexity of the mold plays a crucial role. A mold with intricate internal structures, fine details, or multiple moving parts will require more time for design, machining, and assembly. For example, a mold for a smartphone camera module with micro - sized features may need additional time for EDM (Electrical Discharge Machining) processes to achieve the required precision.

The manufacturer's production schedule also impacts the lead time. If a factory is already fully booked with other projects, it may have to queue your order, potentially increasing the overall lead time. Additionally, factors like the availability of raw materials and the complexity of the supply chain can cause delays. For instance, if a particular type of high - grade steel used in the mold is in short supply globally, it can hold up the production process.

How can I ensure the quality of injection molds from a Chinese manufacturer?

Ensuring the quality of injection molds from a Chinese manufacturer requires a multi - faceted approach. First, check the manufacturer's certifications. Certifications such as ISO 9001:2015 for quality management systems are a good indication that the manufacturer follows standardized quality control processes. For industry - specific molds, like those for the automotive industry, IATF 16949 certification is highly desirable.

If possible, visit the manufacturer's factory. This allows you to assess their production facilities, the condition of their equipment, and the overall organization of their operations. Observe how they handle raw materials, the cleanliness of the production area, and the presence of quality control checkpoints during the manufacturing process.

Request samples of their previous work or ask for a trial production run of your mold. This gives you the opportunity to physically inspect the mold's quality, check for dimensional accuracy using precision measuring tools, and test its performance in a real - world production scenario. You can also perform a sampling inspection of the final injection - molded products to ensure they meet your quality standards.

Furthermore, it's essential to have a detailed quality agreement in the contract. This agreement should clearly define the quality requirements, acceptable defect levels, and the process for handling quality issues, such as returns, replacements, or repairs.

What are the common payment terms when working with Chinese injection mold manufacturers?

- Pre - payment: Many Chinese injection mold manufacturers require a pre - payment, often ranging from 30% - 50% of the total mold cost. The advantage of this for the manufacturer is that it provides funds to start the production process, cover initial material purchases, and ensure a commitment from the client. For the client, it shows good faith but also carries a risk. If the manufacturer fails to deliver as promised, getting the pre - payment refunded can be a complex process.

- Payment upon Delivery: Paying the full amount when the mold is delivered is another option. This gives the client more control as they can inspect the mold before making the final payment. However, manufacturers may be hesitant to accept this term as they bear the cost of production upfront without any financial security during the manufacturing period.

- Installment Payments: This is a popular option where the payment is divided into multiple stages. For example, a common structure is to pay 30% as a down - payment, 50% when the mold is in the final production stages and ready for inspection, and the remaining 20% after successful delivery and acceptance. This balances the interests of both parties. The manufacturer gets some initial funds to start production, and the client can ensure the quality at each stage before making further payments.